DIGITAL SANDWICH

Digitising the sandwich supply chain to tackle food waste, operational inefficiency and improve consumer safety.

Oct 2020 - Mar 2021

Systems

Service Design

Research

The Challenge

The UK produced 9.5m tons of food waste in 2021. The food and drink industry need to ensure consumer safety, sustainable practices and reducing waste. The current inefficiencies occur due to outdated systems which limit trust and promote harmful practices.

The Solution

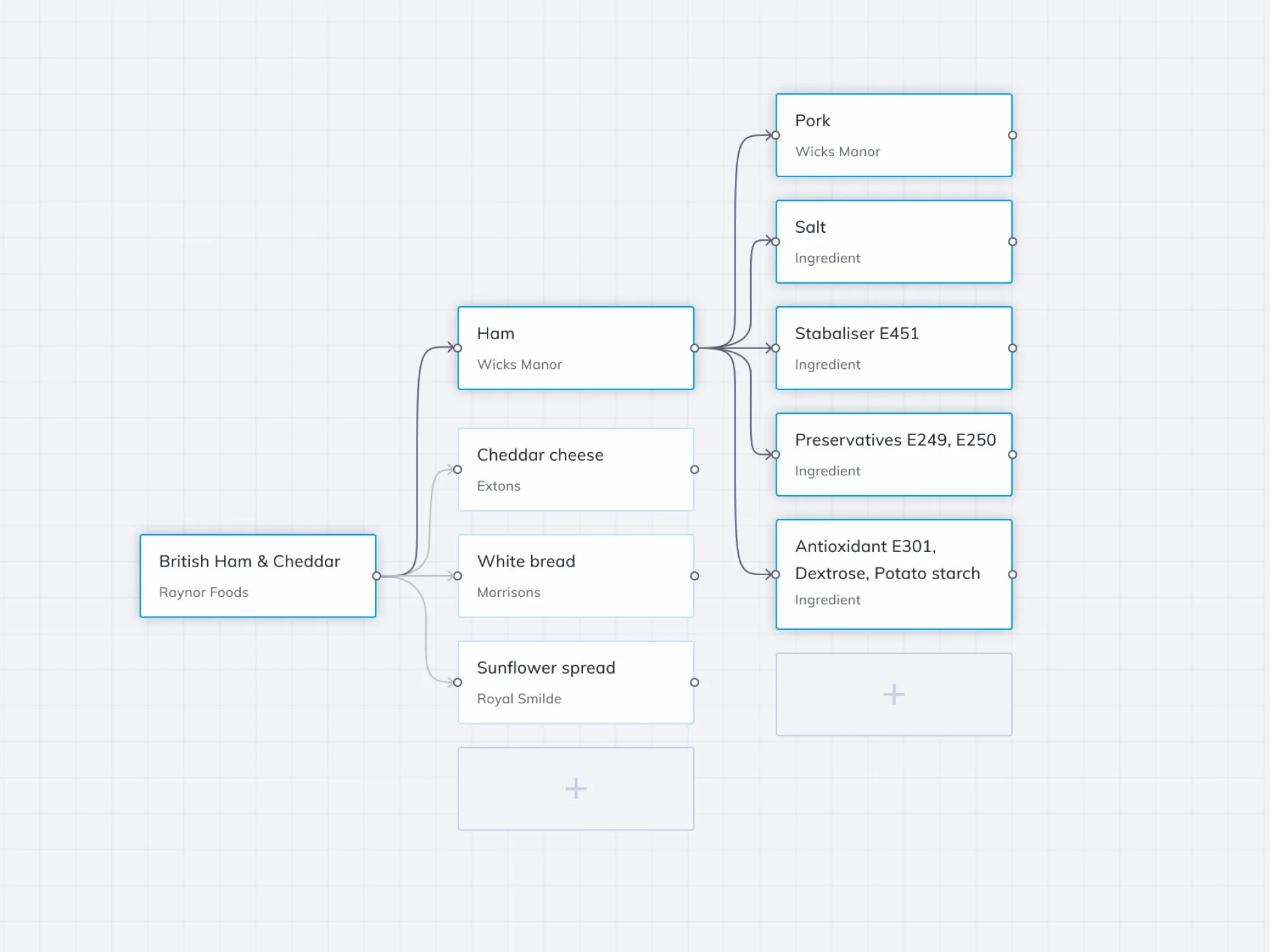

As part of an Innovate UK funded project, we fused IoT, Blockchain and AI to improve productivity, traceability and reduce waste. Current solutions cannot trace ingredients back to their original source. To do this, we needed to know what happens inside each business and track the movement and conversion of each item.

The Process

-

An in-depth, collaborative discovery phase was allowed us to understand the people, processes and challenges on the ground first-hand. This included reviewing systems, stakeholder interviews, service safari, workshops and user interviews.

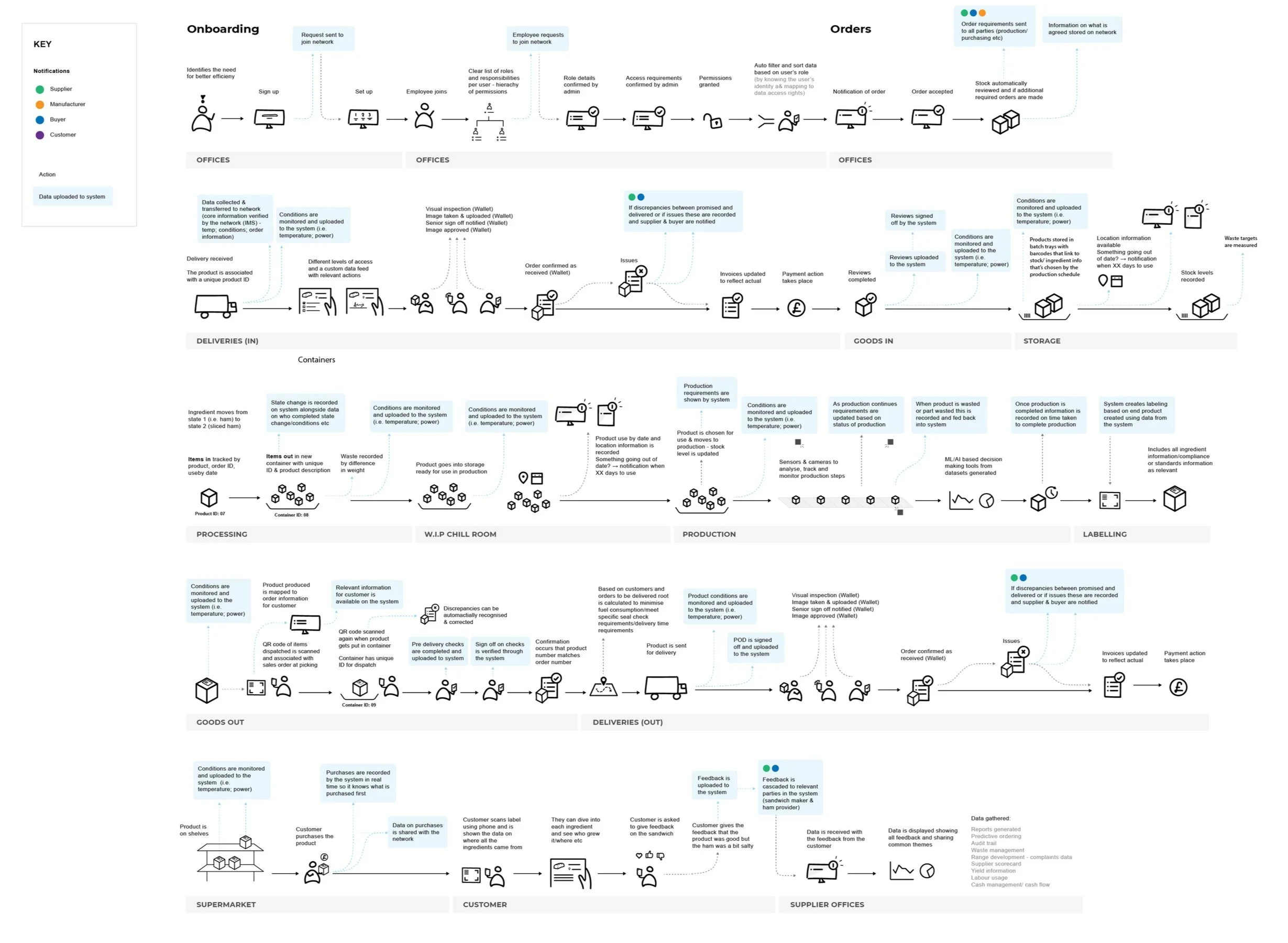

The insights were synthesised and mapped, across a flow diagram, highlighting where the challenges occurred and what impact across the supply chain. This made it immediately clear where the most significant issues lay and what was causing them. -

A visual sketch of potential solutions helped demonstrate how the solution would work, where the technology would be integrated, and who get’s notified at each data collection stage.

After sharing and discussing this with the consortium, we captured the gaps or unknowns and collectively ideated around these areas. I designed and conducted workshops engaging over 30 participants to facilitate discussions and refine the technical aspects of the solution.

-

Every step in the concept diagram was very complex, so we broke it down into manageable sections, allowing us to narrow in on the execution, whilst keeping the broader picture in mind.

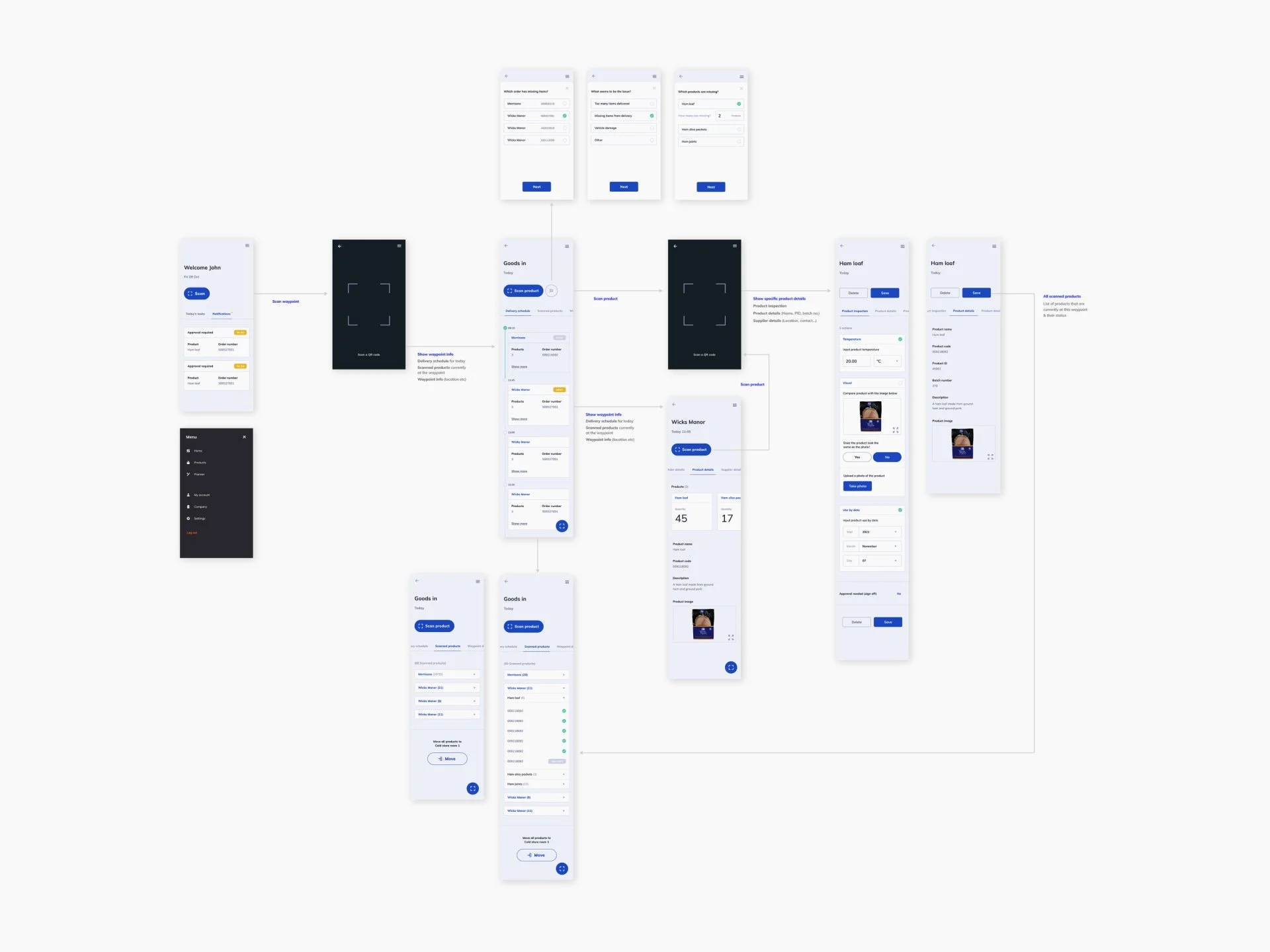

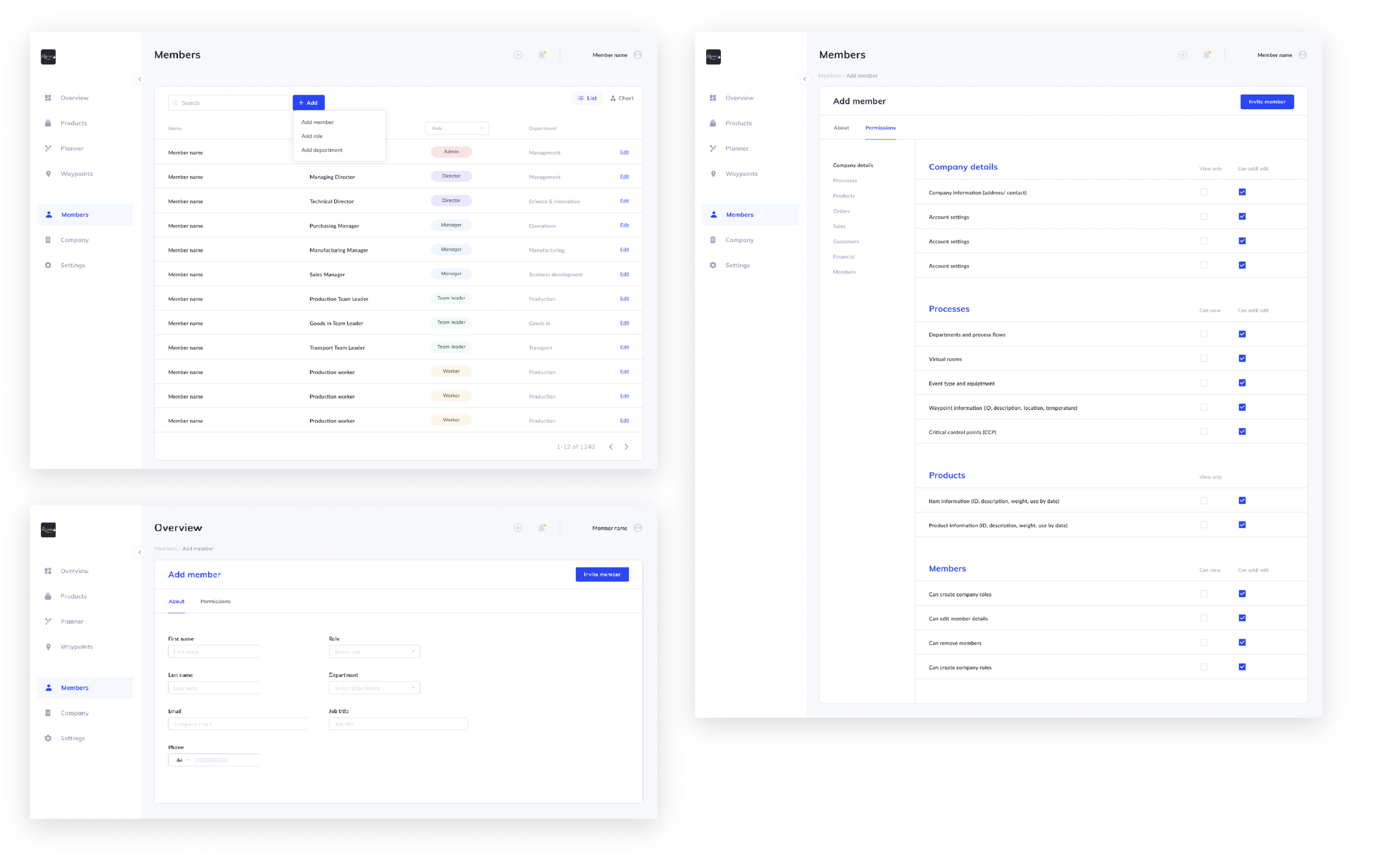

We designed a flexible platform for staff to enter data, such as ingredient details, processes, roles, waypoints, inspection events, and more. This acted as a ‘planner’ and source of truth for how each ingredient should move through the factory.

I also designed and prototyped the app used by ‘goods-in’ and other roles to manage products, from the factory floor.These designs formed the interface for the digital twin capabilities to enable traceability and efficiency.

-

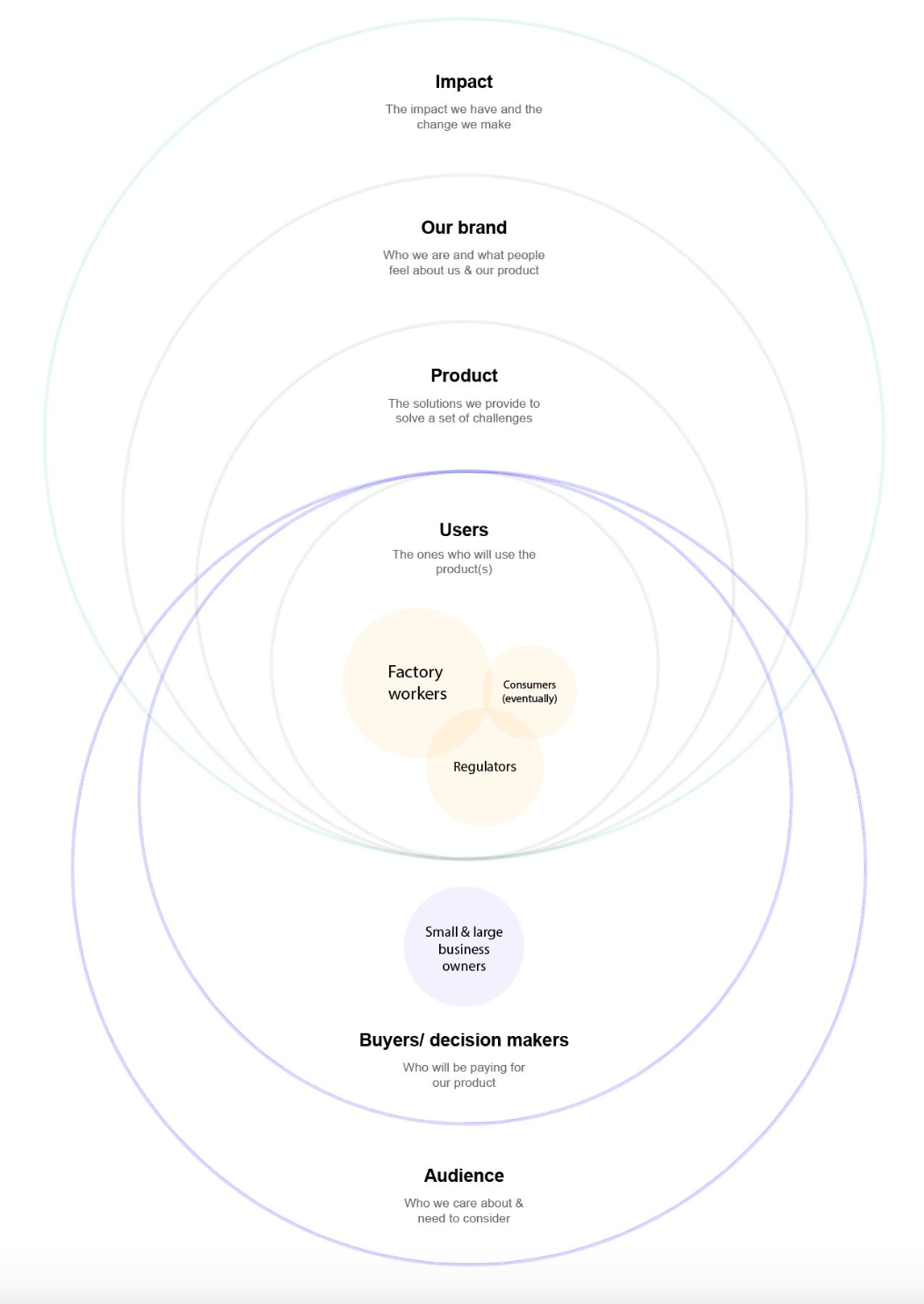

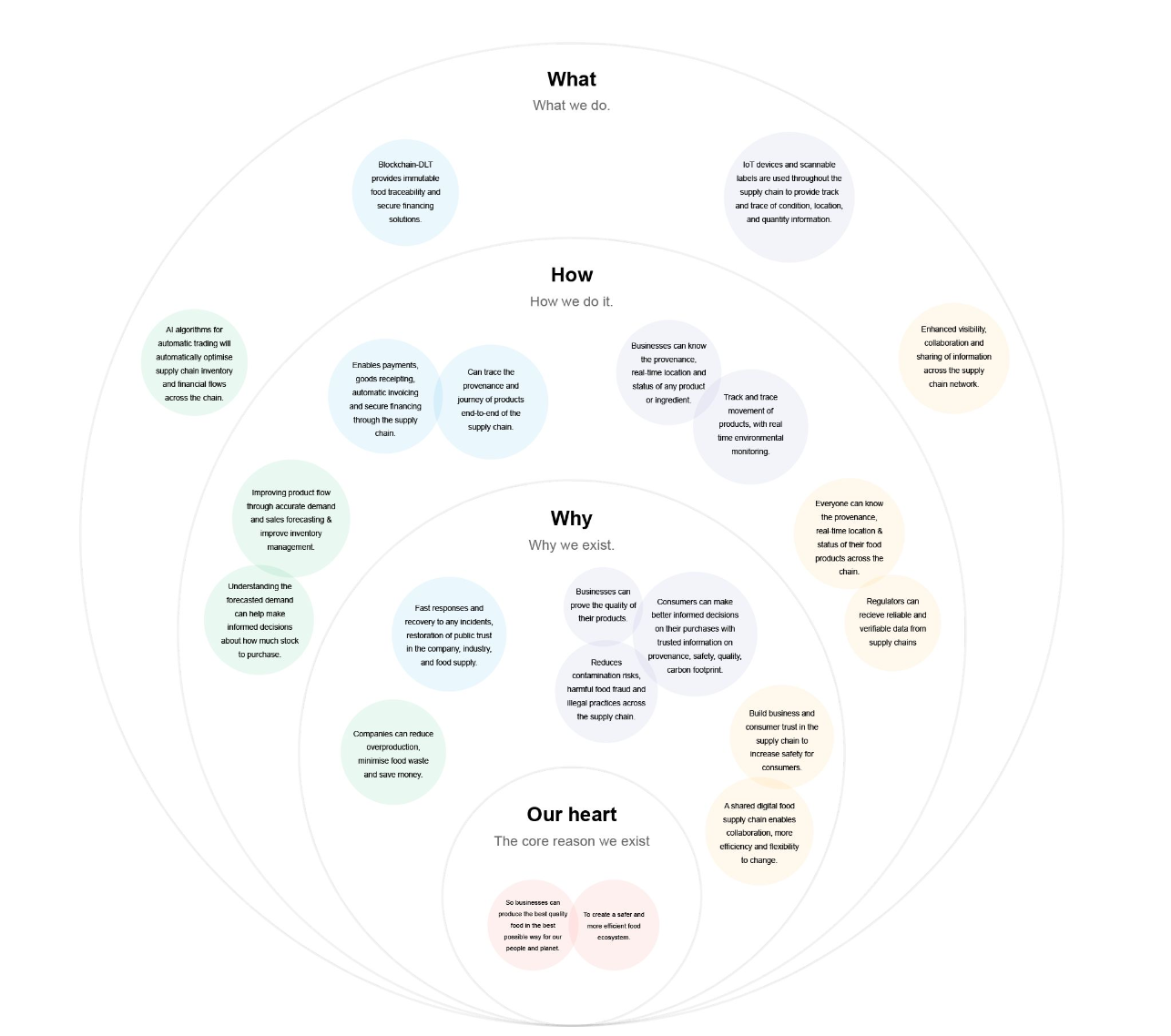

The brand identity I created played a crucial role in aligning everyone around a shared vision, mission and values.

It also covered positioning, value proposition, audiences, market research and visual concepts.

It prompted important questions and gave the project a sense of life, enforcing it in being something people could believe in and rally behind.

The Result

In 2023 the team successfully launched the national demonstrator. Together, we are one step closer to fully resilient supply chains that efficiently predict and respond to change, by providing full visibility every product, ingredient and transaction across the supply chain.

The final solution has potential for application in other sectors including NHS, pharmaceuticals and aerospace.

Every customer can find a unique QR code printed on every Raynor’s sandwich that unlocks every stage of the product's sourcing and manufacture.

Learnings

Working within a large consortium highlighted the importance of building alignment around a shared vision. I found that simplifying complex ideas and making them visual really to give people something tangible to gather around, discuss, and make decisions with confidence.

Gaining an in-depth understanding of the sandwich industry, from processes and products to roles, systems, and day-to-day activities, was key to making the project successful. It reinforced the value of asking the right questions and exploring challenges from multiple angles to uncover meaningful insights and opportunities.